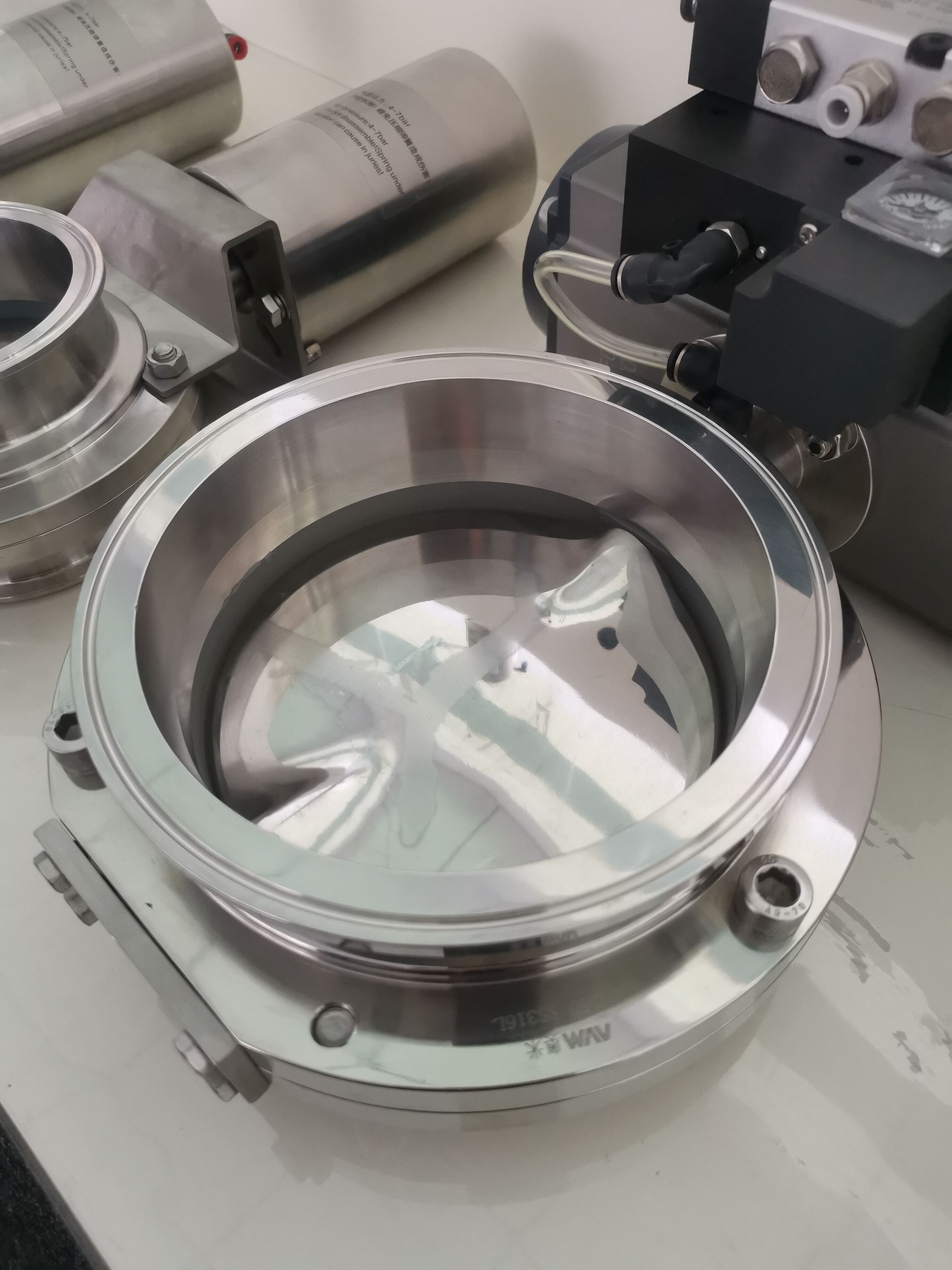

Sanitary Butterfly Valves for Clean and Hygienic Fluid Control in Food and Pharma Industries

Sanitary Butterfly Valves are designed to meet the stringent hygiene standards required in food, beverage, and pharmaceutical industries. These valves are constructed from stainless steel and feature smooth surfaces, minimizing the risk of bacteria growth or contamination. They are used to regulate the flow of fluids in hygienic processes, and their simple design allows for easy maintenance and cleaning. By utilizing a rotating disc to control flow, these valves offer a compact, efficient solution that ensures both operational reliability and hygienic standards are maintained. In addition to their use in food and pharma, Sanitary Butterfly Valves are also suitable for use in cosmetic and chemical manufacturing, where purity and sanitation are critical.

Get A Quote