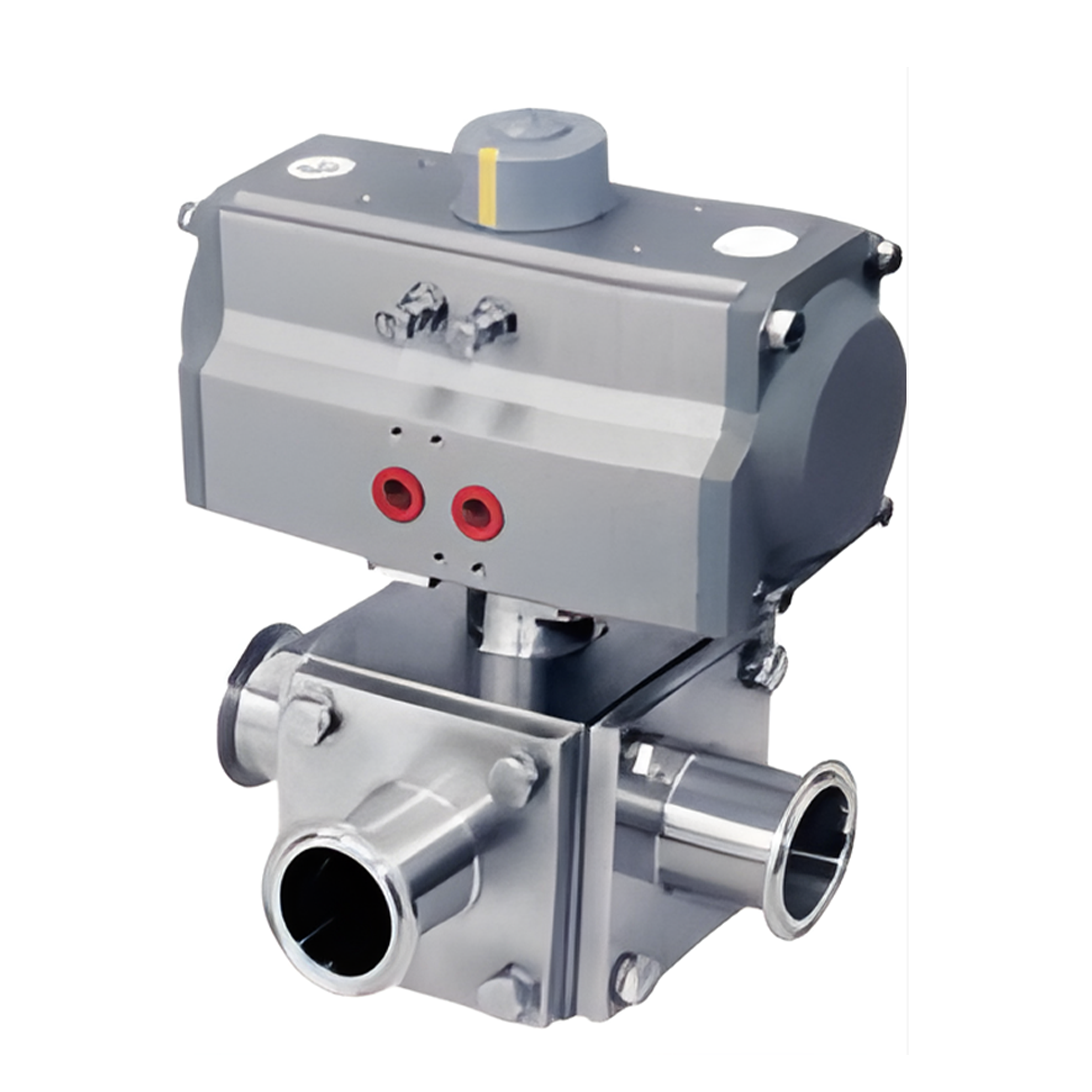

Hygienic Valves for High-Standard Sanitary Applications in Food and Biopharma Industries

Hygienic Valves are built to meet the rigorous standards required for sanitary processes in food processing, pharmaceuticals, and other health-related industries. Designed for easy cleaning and sterilization, these valves feature smooth, corrosion-resistant surfaces and are free from crevices where bacteria can accumulate. With a focus on ensuring hygiene during production, Hygienic Valves are ideal for applications where contamination risks need to be minimized. These valves are crucial for maintaining product integrity and quality, and they play an important role in complying with strict industry regulations.

Get A Quote