Aseptic Transfer Systems for Maintaining Sterility in Sensitive Material Transfers

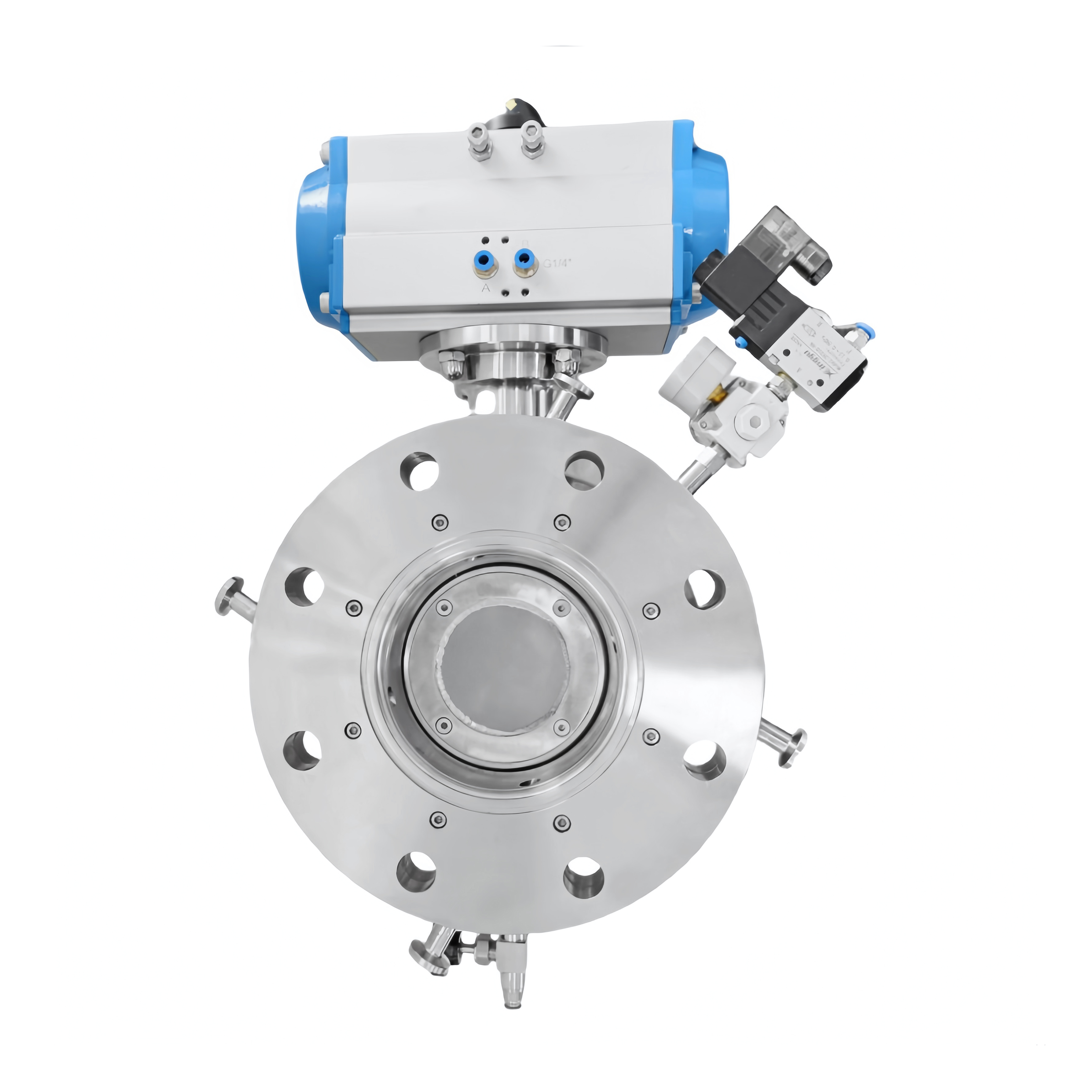

Aseptic Transfer Systems are designed to maintain a sterile environment during material transfers in industries like pharmaceuticals, biotechnology, and food production. These systems ensure that materials are transferred without compromising their sterility, thus preventing microbial contamination. Rapid Transfer Ports (RTPs), used in conjunction with aseptic systems, allow for the safe movement of materials between cleanroom zones without the risk of contaminating the material or the environment. These systems are essential for maintaining product quality and safety in industries that require the highest standards of cleanliness and sterility throughout the production and transport process.

Get A Quote