The Critical Role of Inflatable Seals in High-Speed Train Aerodynamics and Acoustics

Addressing Aerodynamic and Acoustic Challenges with Inflatable Train Door Seals

When high speed trains hit around 300 km/h or faster, they face serious aerodynamic forces that can reach over 2 kPa. These forces create big pressure differences across train doors which really tests how well they stay sealed. Standard rubber seals just aren't cutting it anymore because temperature changes between -30 and +30 degrees Celsius plus all those constant vibrations make gaps form where air can leak through. That's why many modern trains now use inflatable seals instead. These special seals expand about 150% bigger when needed, so they fit into any odd shaped gaps that appear. The result? Much quieter cabins inside since outside noise drops by roughly 12 to 15 decibels. This makes life easier for train companies who need to follow strict EU rules about noise levels set out in the 2020/367 directive.

How Inflatable Seals Compensate for Gap Variations Under Dynamic Operating Conditions

Inflatable seals work around three main causes of gaps changing size: when structures bend during acceleration and braking moments, differences in how aluminum doors expand compared to composite carriages when temperatures change, and gradual wear that builds up after hundreds of thousands of door openings (often exceeding 500,000 cycles). These seals adjust by controlling their internal pressure, usually somewhere between 2 and 6 bar. This keeps the seal tight enough with a margin of about half a millimeter to just over a millimeter. Even when there are sudden pressure drops, like when entering tunnels or passing other vehicles at high speed, the seals still hold up pretty well against those challenges.

Case Study: Noise and Pressure Control in Shinkansen and TGV High-Speed Trains

We're seeing real improvements from recent applications of this technology. Take the new Japanese Shinkansen N700S trains for example - they've managed to cut down noise coming through doors by about 40% when passing through tunnels thanks to those special inflatable seals. And over in France, the TGV M prototypes have shown something interesting too. When strong winds hit these trains, the same sealing tech keeps cabin pressure changes under control at around 200 Pa per second or less. That means passengers don't get that uncomfortable feeling in their ears anymore. What all this shows is that modern train designs are getting better at both soundproofing and managing air pressure inside cabins, which makes rides much more comfortable overall.

Growing Adoption of Inflatable Seals in Next-Generation High-Speed Rail Systems

Inflatable seals are becoming the norm these days for about three quarters of all new high speed rail developments throughout Europe and parts of Asia. Why? Well, there's this whole thing about meeting newer industry standards like ISO 22180 from 2023 which deals specifically with how air flows around train components, plus EN 45545-2 regarding fire safety requirements. But it's not just about ticking boxes on regulatory forms either. The real game changer comes down to how long these seals actually last compared to traditional silicone ones. We're talking roughly 30 to maybe even 50 percent longer before needing replacement. That means fewer times mechanics have to climb around trains doing maintenance work, which obviously cuts down both labor costs and overall expenses when running large public transport networks.

Activation Mechanisms and System Integration of Inflatable Seals in Rail Applications

Inflation and Deflation Cycle: Durability and Operational Lifespan of Inflatable Seals

Inflatable seals today can last well beyond 100 thousand inflation cycles before showing any signs of wear, primarily because they're made from tough elastomers that have extra layers against abrasion. Research conducted across various European train systems back in 2023 showed something interesting too. The dual chamber seal designs kept about 98 percent of their original compression strength even after sitting through eight full years of constant use. What makes these seals so long lasting? Several important design elements work together. First off, the materials used meet the EN 45545:2015 standards which means they resist fires better. Then there's the wall thickness, usually between 2.5 and 4 millimeters thick, preventing the material from getting overstressed during operation. And finally, most modern designs come with built in pressure relief valves that stop the inflation process once it reaches around 8 pounds per square inch, keeping everything within safe limits.

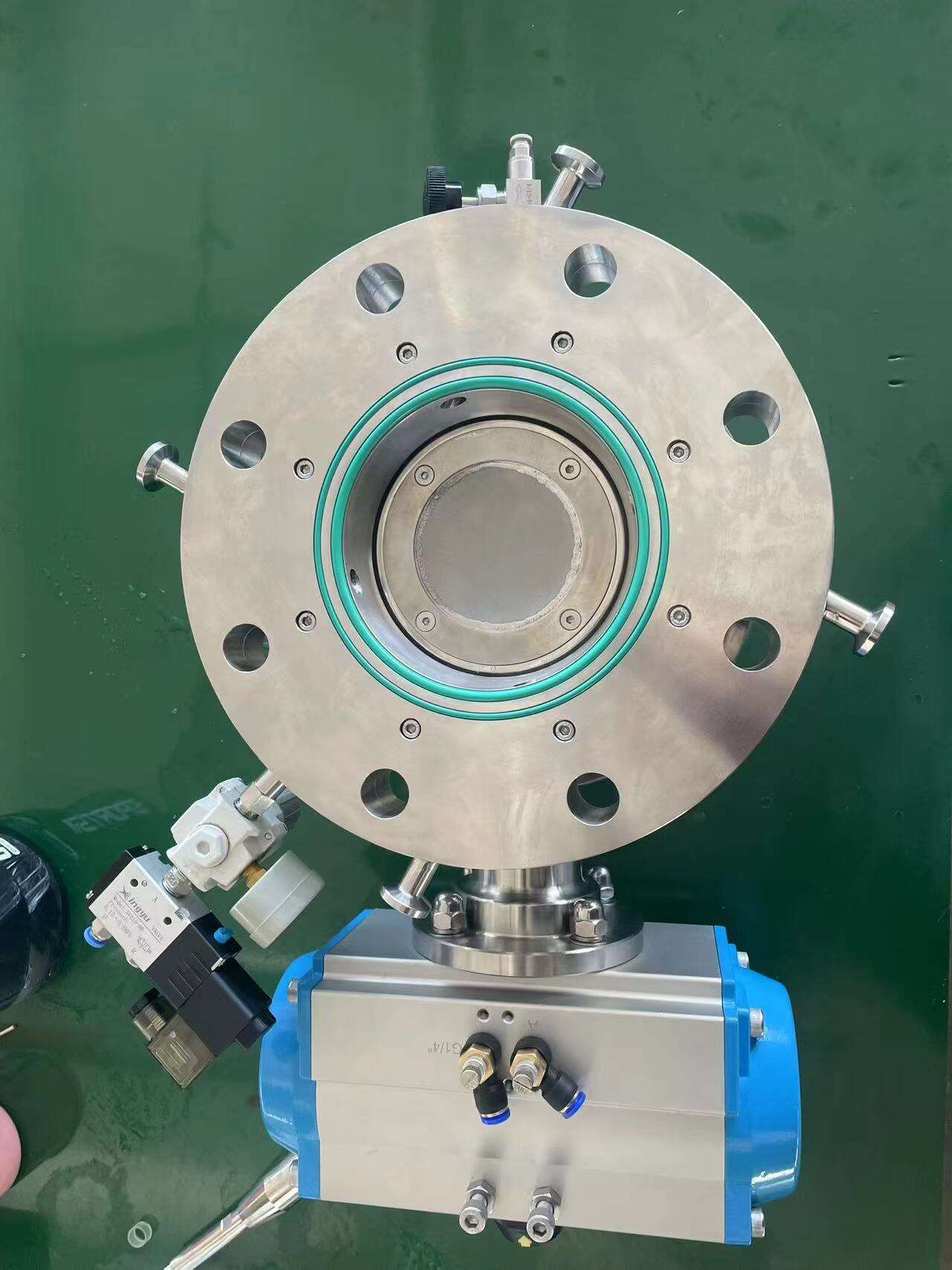

Pneumatic Control Systems for Precise and Timely Seal Deployment

Microprocessor-controlled pneumatic systems deploy seals within 0.5–1.2 seconds, responding to real-time cabin pressure data. These systems ensure reliable performance under diverse conditions, including altitude changes up to 2,500 meters–critical for routes like the Gotthard Base Tunnel. Specifications for modern control units include:

| Parameter | Specification |

|---|---|

| Response Time | <0.5 seconds |

| Operating Pressure | 6–8 psi |

| Leak Rate | <0.1% volume loss/hour |

This level of precision enables seamless integration into automated train operations while maintaining long-term reliability.

Synchronization with Door Actuation Systems for Reliable Seal Activation

The seals work together with the door system so they start inflating around 200 milliseconds before the door actually closes, staying inflated right up until someone opens it again. When tested on Italy's ETR 1000 trains, these systems showed amazing results too - about 99.9% reliability after going through 15 thousand cycles. How? Well, there are backup sensors that can detect position within just one millimeter, plus two separate air channels for redundancy. The pressure gets monitored constantly with measurements down to tenth of a pound per square inch. All this makes sure everything keeps working properly even when conditions get tough in real world situations where doors might be slammed shut or exposed to extreme weather.

Material Selection and Environmental Resilience of Inflatable Seals

Choosing the right materials matters a lot when dealing with harsh environments. EPDM continues to dominate the market at around 68%, mainly because it stands up well against ozone damage and works reliably between minus 40 degrees Celsius and plus 120. For places where temperatures swing wildly like Arctic regions or hot deserts, silicone becomes the go-to option since it can handle much wider extremes from negative 80 all the way up to 230 degrees. Coastal installations often rely on fluorocarbon though, as this material resists chemicals far better than EPDM does. Tests show fluorocarbon lasts about four times longer in saltwater exposure according to standard industry assessments, which explains why many manufacturers specify it for marine applications despite higher costs.

Reinforcement Fabrics for Enhanced Structural Integrity Under Pressure

Modern seals need to handle high internal pressure while preventing too much sideways expansion, so manufacturers often add aramid fiber or polyester mesh layers as reinforcement. These materials cut down on radial growth by about half when operating at 3 bar pressure compared to regular seals without such reinforcement. What's more important is how they perform over time. After running through a million cycles at 2 Hz frequency, these reinforced seals still keep deflection under 0.5 mm. That kind of stability matters a lot for maintaining an airtight seal even when vehicles reach those crazy speeds around 300 km/h. Without this kind of engineering, the seals would fail long before reaching such demanding conditions.

Impact of UV Exposure, Ozone, and Temperature Extremes on Seal Longevity

Tests that speed up the aging process reveal silicone materials break down quicker when exposed to UV light in subtropical climates. After about 5,000 hours of exposure at 85 watts per square meter, these silicones lose around 40% of their original elasticity. Fluorocarbon materials tell a different story though, maintaining roughly 90% of their flexibility even after similar testing periods. Looking at real world applications, field data collected along Japan's Tokaido Shinkansen high speed rail line shows something interesting too. The EPDM fabric composite seals used there have been lasting approximately seven years on average, which is quite impressive considering the local ozone levels regularly go above 80 parts per billion according to the JR East Maintenance Report from 2023. These findings highlight how material selection matters significantly depending on environmental factors.

Balancing Flexibility and Long-Term Material Degradation in Harsh Environments

The most effective seal designs combine reinforcement fabrics with elastomers matched to specific environmental stressors–EPDM for high-ozone zones, HNBR for fuel exposure, and silicone for severe thermal cycling. This tailored approach has reduced replacement frequency by 60% in the TGV Mediterranean fleet based on 15 years of operational data.

Design and Engineering Considerations for Custom Inflatable Seals

Defining Geometry and Expansion Direction: Axial vs. Radial Inflation

The shape of seals plays a big role in how well they work across different types of doors. When we talk about axial inflation, which basically means expanding along the direction of the door frame, these kinds of seals tend to perform best on flat surfaces where there's no curve involved. They create pretty even pressure throughout the contact area. On the other hand, radial inflation works better when dealing with those tricky curved or irregular spaces because it expands outward from the mounting point instead. Industry research from last year indicated that radial seal designs cut down on air leaks by around 15-20 percent compared to traditional options when applied to doors with complex shapes or angles. This makes them particularly useful for commercial buildings where perfect alignment isn't always possible between door frames and walls.

| Inflation Type | Pressure Range (kPa) | Gap Compensation | Typical Use Case |

|---|---|---|---|

| Axial | 40–60 | ±5 mm | Straight door frames |

| Radial | 70–90 | ±12 mm | Curved/angled interfaces |

Optimizing Inflation Pressure for Effective Sealing and Passenger Comfort

Getting the pressure right during calibration is essential for good sealing while keeping doors from getting damaged or becoming unsafe. If there's not enough pressure, air might leak through gaps. But crank it up too high and parts start to bend out of shape. Modern control tech keeps things running between about 55 to 75 kilopascals. Tests done last year showed this range cuts down noise levels by around 6.2 decibels according to RailTech research. The system finds that sweet spot where it quiets things down without wearing itself out prematurely.

Integrating Inflatable Seals Early in the Design Process to Avoid Retrofitting

Early integration during CAD modeling prevents costly redesigns later in development. According to the Transit Engineering Journal (2021), proactive seal inclusion reduces late-stage modifications by 82%. One Japanese operator cut prototype iterations by 65% after adopting parametric seal models synchronized with door actuator simulations.

Collaborating with Seal Manufacturers During Initial Design Phases

Engaging seal manufacturers early allows for material compatibility testing under real-world conditions. A European trainbuilder reduced vibration-induced failures by 41% by co-developing fabric-reinforced silicone profiles during concept validation, rather than waiting until production tooling. This collaborative engineering approach enhances reliability and shortens time-to-market.

Mechanical Integration and Performance Advantages of Inflatable Seals

Retaining Methods: Mechanical Clamping vs. Adhesive Bonding

When it comes to keeping things aligned properly, mechanical clamping really stands out. A recent study from 2024 on rail engineering found that these systems maintained about 92% of their initial position even after going through half a million inflation cycles. On the other hand, adhesive bonding can cut down door system weight somewhere between 18% and 22%. The catch though is that surfaces need pretty thorough prep work if they're going to handle those +/- 2.5 mm side movements when trains are moving fast. For sealing applications, fabric reinforced inflatable seals actually hold up three times better against tearing compared to regular solid designs. This makes them work well with either clamping or bonding approaches as long as we stay within normal rail pressure ranges around 0.8 to 1.2 pounds per square inch.

Preventing Misalignment and Extrusion During Inflation Cycles

The precision molded channels keep lateral expansion below 0.4mm when inflating quickly, which is really important for staying aligned at speeds over 300 km/h. We've embedded cross reinforced nylon webbing that cuts down on stress points by around two thirds according to research from the Polymer Engineering Journal last year. This helps stop any material from being pushed out even when facing emergency braking forces up to 1.8G. Field tests have shown these seals maintain their airtight integrity through something like ten million pressure cycles. That's basically what we'd expect after 25 years of heavy duty operation in real world conditions.

Lightweight Design and Lifecycle Cost Benefits Over Rigid Sealing Systems

Using inflatable seals cuts down on door assembly weight by somewhere between 40 to 60 percent when compared to traditional metal gaskets, which translates into around 12 thousand kilowatt hours saved each year for every train set. The modular design means mechanics can replace just the damaged sections rather than tearing out entire systems during maintenance checks, something that has cut repair bills by roughly a third over ten years according to industry reports. These seals work particularly well when made from EPDM materials that resist corrosion, lasting well beyond eight years even in tough coastal conditions where salt air would normally eat away at standard rubber components within months.

FAQ Section

What are inflatable seals used for in high-speed trains?

Inflatable seals in high-speed trains are used to maintain airtight sealing in dynamic conditions, reducing noise by 12 to 15 decibels and adhering to EU noise regulations.

How do inflatable seals compensate for gaps due to train movements?

Inflatable seals adjust their internal pressure, typically between 2 and 6 bar, to adapt to structural changes due to acceleration, braking, and temperature variations.

Which materials are commonly used for inflatable seals?

Common materials for inflatable seals include EPDM for high-ozone environments, silicone for extreme thermal conditions, and fluorocarbon for marine applications.

What advantages do inflatable seals offer compared to traditional seals?

Inflatable seals offer advantages such as better durability, longer lifespan, lightweight design, and enhanced sealing integrity in demanding environments.

Table of Contents

-

The Critical Role of Inflatable Seals in High-Speed Train Aerodynamics and Acoustics

- Addressing Aerodynamic and Acoustic Challenges with Inflatable Train Door Seals

- How Inflatable Seals Compensate for Gap Variations Under Dynamic Operating Conditions

- Case Study: Noise and Pressure Control in Shinkansen and TGV High-Speed Trains

- Growing Adoption of Inflatable Seals in Next-Generation High-Speed Rail Systems

- Activation Mechanisms and System Integration of Inflatable Seals in Rail Applications

- Material Selection and Environmental Resilience of Inflatable Seals

- Design and Engineering Considerations for Custom Inflatable Seals

- Mechanical Integration and Performance Advantages of Inflatable Seals

- Retaining Methods: Mechanical Clamping vs. Adhesive Bonding

- Preventing Misalignment and Extrusion During Inflation Cycles

- Lightweight Design and Lifecycle Cost Benefits Over Rigid Sealing Systems

- FAQ Section