The Function of Aseptic Transfer Systems in Sterile Production Â

Â

Aggressive Preventative Measures to Avoid Contamination for Pharmaceutical Production Â

Â

Getting aseptic transfer systems up and running along with those controlled isolation areas really cuts down on contamination during material transfers in drug manufacturing. These systems typically include special filters and valves that create clean paths for air and vapors while keeping contaminants at bay. Research indicates around one third of all medication contamination issues actually come from flaws in transfer systems themselves. That's pretty staggering when you think about it. Regulatory agencies now insist that companies stick strictly to good aseptic practices to stop microbes from getting into clean zones where they could harm patients. For anyone working in clean rooms, this means these systems aren't just nice to have but absolutely essential for maintaining product quality and patient safety.

Â

Important Uses in Vaccine and Biologics Manufacturing Â

Â

When making vaccines, particularly during urgent responses to disease outbreaks, keeping track of product quality becomes absolutely essential. Without proper safeguards, even small mistakes can ruin entire batches. That's where aseptic transfer systems come into play as they help maintain the necessary sterility throughout production. Biologics used in healthcare are far more delicate than regular medications, so manufacturers need extra precautions against contamination. This has led to developments such as Rapid Transfer Ports (RTPs) which make the whole manufacturing process faster and more efficient. Industry professionals estimate that implementing strong aseptic transfer protocols might boost biologics production capacity by around half, which underscores just how crucial these procedures are for ensuring both safety standards and overall product quality across different facilities worldwide.

Â

Keeping things sterile when moving materials around is where closed systems really shine because they stop outside stuff from getting in. The ergonomics built into these systems actually help operators move through clean areas without risking contamination. Plants that implement this kind of design see real benefits both in staying competitive against regulations set by global standards organizations and experiencing fewer contamination problems overall. Pharmaceutical manufacturers who've switched to closed system approaches have seen tangible results in their operations, with much better control over sterility levels than traditional methods allowed.

Â

As you can tell, the effectiveness of aseptic transfer systems preserves the safety of pharmaceutical products during production and distribution.

Â

Core Technologies Enabling Aseptic Material Transfer Â

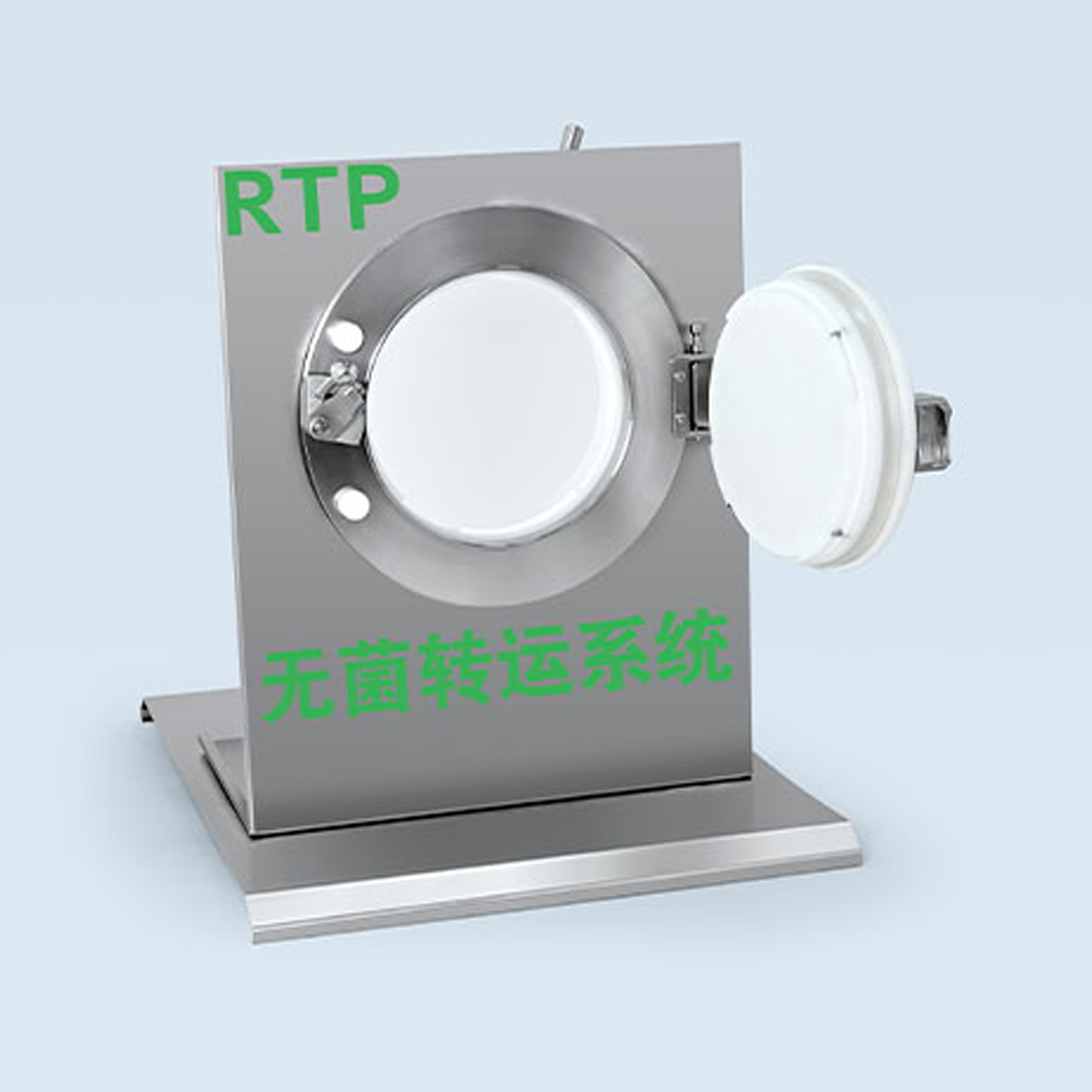

Rapid Transfer Ports (RTPs) for Safe Product Handling Â

Â

Rapid Transfer Ports (RTPs) play a vital role in moving sterile materials safely while keeping environments free from contaminants. Their importance grows when looking at how they help reduce contamination risks throughout product transfers. Research shows that facilities using RTP technology tend to see improvements in both safety measures and overall productivity when dealing with delicate biological substances. Most experts recommend regular updates to RTP systems if manufacturers want to maintain their effectiveness for proper sterilization processes. This becomes even more critical considering how fast regulations change in pharmaceutical production these days.

Â

Isolators vs RABS Barrier Systems Comparison Â

Â

Isolators and Restricted Access Barrier Systems (RABS) both play key roles in controlling contamination, though they serve very different purposes. An isolator creates a totally sealed environment, making it ideal for applications requiring maximum sterility levels. On the other hand, RABS systems let operators get their hands on the process more directly while still keeping contaminants at bay. When looking at the numbers, isolators generally come with bigger price tags up front, but they deliver superior protection when working with delicate materials. The industry seems to be moving toward RABS solutions more often these days, especially when production timelines matter most and manufacturing needs change frequently.

Â

Diaphragm Valves in Fluid Control Applications Â

Â

Diaphragm valves play a key role in managing fluid flow within aseptic transfer systems, mainly because they create tight seals that stop leaks from happening. In sterile processing environments, these valves help maintain cleanliness by precisely metering products during transfers, which cuts down on waste significantly. The pharmaceutical and food processing industries have long preferred diaphragm valves for their dependable operation under clean conditions. Facilities rely on them not just for efficiency but also to meet strict FDA and GMP standards when it comes to keeping production areas free from contamination risks. Without proper valve function, even minor breaches could compromise entire batches worth thousands of dollars.

Â

Pneumatic Systems for Automated Transfer Operations Â

Â

Pneumatic systems play a vital role in automating transfer processes, cutting down on manual labor and reducing the risk of contamination. The special valves used in these systems help keep things sterile while still allowing for precise control during material transfers. Manufacturing plants that have switched to automated pneumatic setups report better workflow efficiency and fewer mistakes happening on the line according to recent industry reports. However, these systems need regular checkups and calibration adjustments to ensure they continue delivering top performance and meeting those strict aseptic requirements that many facilities operate under daily.

Â

Regulatory Compliance and EU GMP Annex 1 Requirements

Â

Primary Changes In Annex 1 Related To Transfer Process Validation

Â

The latest EU GMP Annex 1 brings a whole new level of attention to validating transfer processes. What this means in practice is that manufacturers now need stronger validation protocols, better control systems, and access to more advanced technologies than before. The regulatory landscape has definitely shifted towards requiring thorough documentation practices and strict compliance with sterile conditions throughout production facilities. Looking at industry statistics, there seems to be around a 40% improvement in compliance rates for companies that have fully adopted these new Annex 1 standards. While implementing such detailed regulations can be challenging, many in the sector are finding that the extra effort pays off in terms of both product quality and operational efficiency.

Â

Contamination Control Strategy (CCS) Implementation

Â

Meeting regulations and maintaining good product quality really depends on following those key industry standards, especially when it comes to controlling contamination. What does this actually mean? Well, companies need to spot potential contamination risks early and set clear limits for what's acceptable during production runs. Some recent studies from industry experts show that implementing proper Contamination Control Strategies can cut down cross contamination incidents by quite a bit during manufacturing processes. Training staff properly on how to handle materials and equipment is another crucial piece of the puzzle. When workers understand these controls, they help keep everything running smoothly. Pharmacies that manage their facilities without constant disruptions tend to get better approval ratings from regulators too. Plus, this kind of approach builds something valuable over time – a genuine commitment to quality throughout the entire manufacturing process.

Â

Document Control Requirements for Validation of an Aseptic System Â

Â

When validating an aseptic system, proper document control means keeping track of every step taken throughout the process, including detailed notes on protocols followed, test results obtained, and any modifications made to the system itself. Getting this right matters because accurate records and clear accountability form the backbone of effective validation practices, which is why many facilities now rely on specialized electronic documentation systems. The evidence shows pretty clearly that when companies maintain thorough documentation, they tend to fare much better during those dreaded regulatory inspections. Good records don't just satisfy auditors either—they actually help identify issues early on before they become bigger problems down the line.

Â

Advances Enhancing Aseptic Transfers Â

Â

Biopharmaceutical Manufacturingâs Single-Use Technologies Â

Â

The use of single-use tech has really boosted how efficient aseptic transfers are in making biopharma products because nobody needs to spend time cleaning or sterilizing equipment between runs. These systems play a big role when companies produce smaller batches or tailor medicines for individual patients since they cut down on cross contamination risks quite a bit. Industry insiders see a real surge coming in adoption rates across the sector. Sure, getting started with these systems costs a pretty penny upfront, but most manufacturers find that their day to day expenses drop off considerably after installation. The fact that operations stay flexible long term while the industry keeps changing at such a fast pace means these technologies aren't just nice to have anymore they're becoming standard practice in modern biopharma facilities.

Â

Robotic Integration for Reduced Human Intervention Â

Â

Adding robots to aseptic transfer processes automates many steps that would otherwise require human hands. This cuts down on contamination risks significantly. The machines just keep doing what they're programmed to do without getting tired or distracted. Manufacturers see real improvements when they switch to automation. Look at clean rooms where robots handle sensitive materials – there's simply fewer mistakes made compared to manual operations. What's really interesting is how well robots handle large volumes of work. They can run non-stop through production runs that used to take days, which explains why so many facilities are turning to robotic solutions these days. These systems aren't just good at preventing errors; they actually make the whole manufacturing process more flexible and responsive to changing demands.

Â

Sustainability Trends in Sterile Transfer Components Â

Â

Sustainability has become the new buzzword across industries, particularly when it comes to minimizing ecological impact during the building of sterile transfer parts. We're seeing manufacturers develop components that can be used multiple times instead of single-use disposables, while also incorporating greener materials into their production processes. Looking at how products perform throughout their entire life cycle reveals something interesting environmental practices actually save money over time while protecting our planet. Beyond just cost savings though, there's another angle worth considering many businesses that commit to eco-friendly approaches in cleanroom manufacturing find themselves viewed more favorably by customers who care about corporate responsibility. This growing awareness is pushing the whole sector toward more sustainable solutions despite initial costs seeming higher upfront.

Â

Â